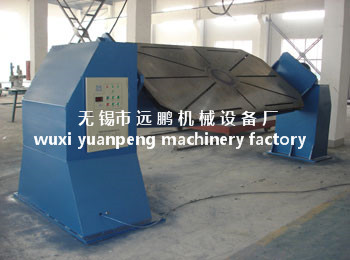

Brief introduction:

Via work table overturning & rotating, manipulate work pieceto correct work position. Work table height adjustable for larger work piecerange.

Feature of Rotary tilting weldingmanipulator :

1. rotary tilting welding manipulatoris mainly composed of worktable rotatingunit and tilting unit and electric control system .

2. It has powered tilting and rotating, making the work-piece at ideal position.

3. Worktable rotation is controlled by step-less frequency conversion toachieve a best welding speed .

4. Rotate unit is driven by motor. It has a precise speed-adjusting andreliable position.

5. Remote control box can realize the remote operation of work bench, also canconnect with operating machines to realize linkage operation.

6. Set aside interface to realize linkage work with manipulator and hangingautomatic welding machine achieve automatic welding center .

7. Used to pressure vessel, metallurgy, electrical power, chemical industry,mechanical and metal structure .

Remark:

1.Work table height fixed or adjustable are option .

2.Voltage is arranged as per your requirement; .

3. Controlled is remote-control box, optional is foot pedal;

4.Beacause of the offset from center and gravity center ,for the longer andmore offset from gravity center workpiece, large model should be chosen. Wewould be pleasure to make solution for you if needed.

Rotary tilting weldingmanipulatordescription:

· Rotarytilting welding manipulator is mainly composed of worktable revolving unit andtilting unit.

· Withworktable lifting, tilting and rotating, it is mainly used to place theworkpiece in the best position for welding and assembling.

· It can beused for various automatic or manual welding, butt welding or face welding ofpipe, as well as welding of shafts, discs, barrel, etc.

· The rotarytilting welding manipulatorseries can divide into side tilting type , head totail rotary type, headstock & tailstock lifting rotary type, headstock& tailstock tilting type, double rotary type positioner.

· The rotarytilting welding manipulator can work with welding column & boom to realizethe automatic special purpose welding center.

Points you may concern:

Customization- Can your machine or other products becustomized?

Ronniewell: Sure. As a professional manufacturer, we have our own engineerteam, who is good at design, develop & build special solution catering foryour individual requirement.

Transportation-What about the transportation?

Ronniewell: Seaway is the most common transportation way for oversea trading.Depends on your location, combined transport by rail and sea is also an option.Certainly railway transportation is also acceptable if it is the most suitableapproach.

After saleservice - What about the after-sale service?

Ronniewell: We provide 12month guaranty period for the whole machine quality.During this time, any issue proved because of the machine flaw itself,we wouldtake the whole responsibility of it. Except of the guaranty period,technicaladvisory support is available freely covering the whole using life of themachine. Engineer service on user premises is also available for necessary.

Type

| Rated Loading(kg) | Rotation Speed(rpm) | Tilting Speed(rpm) | Tilting Angle(▲) | Worktable Dia(mm) | Rotation power(kw) | Tilting power(kw) | Way of setting | Max Eccentricity(m) | Max. Gravity(mm) |

| HBS-50 | 500 | 0.05-0.5 | 0.2 | 0÷90 | 2500 | 3

| 2≠2.2 | AC frequency conversion stepless speed regulation | 200

| 600

|

| HBS-100 | 1000 | 0.05-0.5 | 0.1

| 0÷90 | 2500 | 4 | 2≠3 | 200 | 600

|

HBS-200

| 20000 | 0.04-0.4

| 0.1

| 0÷90

| 3000 | 5.5 | 2≠5.5

| 200

| 1000 |

| HBS-300 | 30000 | 0.03-0.3

| 0.1

| 0÷90

| 3500 | 7.5 | 2≠7.5

| 200

| 1500 |

HBS-500

| 50000 | 0.02-0.2

| 0.1

| 0÷90

| 4000 | 11 | 2≠11

| 200

| 2000 |

| HBS-1000 | 100000 | 0.01-0.1 | 0.1 | 0÷90

| 4000 | 18.5 | 2≠15

| 200 | 2500 |